In the high-stakes world of Controlled Environment Agriculture (CEA), horticultural grow lights are the ultimate currency. As growers strive for year-round consistency and higher yields, the technology used to bridge the gap between natural sunlight and crop requirements has evolved through three distinct “Eras”.

Understanding the strategic strengths of Fluorescent, HID (HPS), and LED technologies—and how they are currently converging—is essential for any commercial operation looking to optimize its ROI.

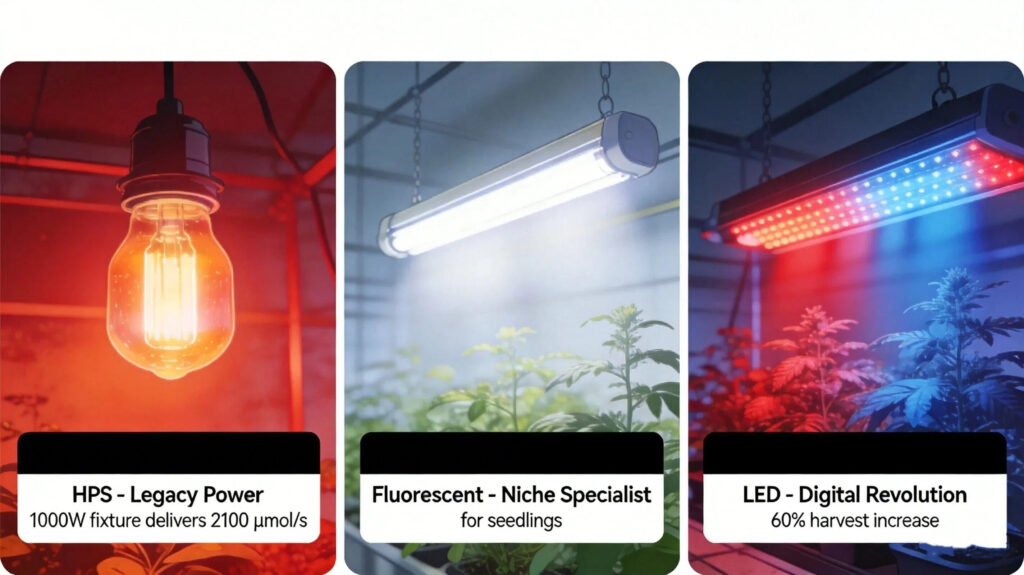

1. The Legacy Power: High-Pressure Sodium (HPS)

For decades, HPS was the undisputed “heavyweight champion” of greenhouse supplemental lighting. Characterized by its intense orange-red glow, HPS mimics the late-summer sun, which is highly effective for stimulating flowering and fruiting in tall-canopy crops like tomatoes and cucumbers.

- The Advantage: Massive photon output (e.g., a standard 1000W fixture can deliver up to 2100 μmol/s) and deep canopy penetration.

- The Constraint: HPS is a thermal light source. Its high operating temperature prevents close-range mounting, making it unsuitable for vertical farming or multi-layer racking. Furthermore, its spectrum is fixed and heavy in yellow-green light, which is less efficient for photosynthesis compared to targeted wavelengths.

2. The Niche Specialist: : Fluorescent Horticultural Grow Lights

Fluorescent tubes have long been the “safe bet” for the earliest stages of plant life. Traditionally found in tissue culture labs and seedling nurseries, they provide a gentle, diffused light.

- The Advantage: Low initial capital expenditure (CAPEX) and uniform light distribution, which protects fragile young tissues from light stress.

- The Constraint: High energy consumption per micromole and a significant “light decay” over time. As LED solutions for nurseries become more cost-effective, the footprint of fluorescent lighting is rapidly shrinking in modern facilities.

3. The Digital Revolution: LED (Light Emitting Diodes)

LED technology is no longer just a “challenger”—it is the architect of the new agricultural frontier. Unlike its predecessors, the LED is a semiconductor, allowing for surgical precision in spectral tuning.

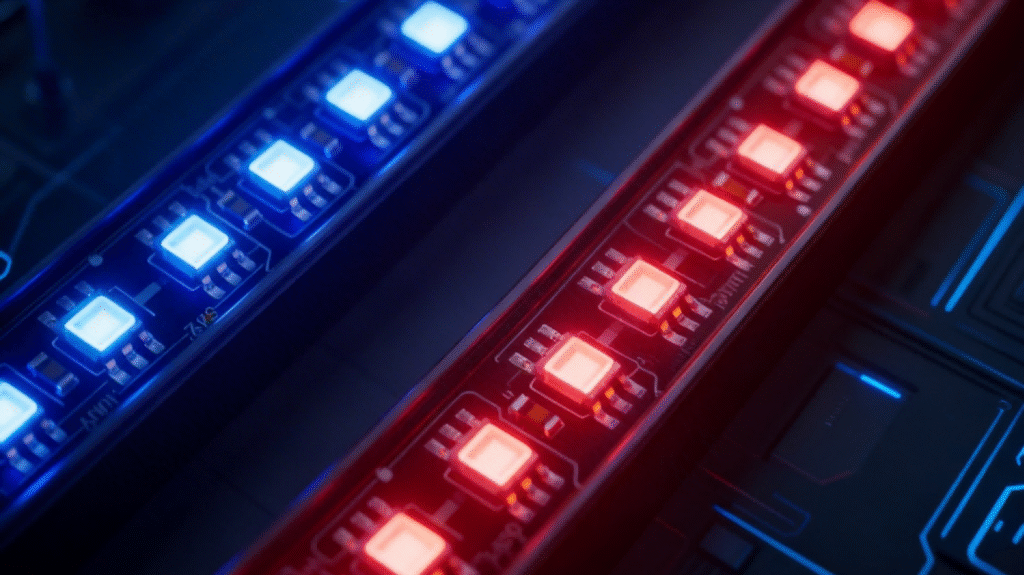

- Efficiency Redefined: Modern LED grow lights can be engineered to emit specific peak wavelengths—most notably Deep Blue (450nm) for vegetative vigor and Hyper Red (660nm) for biomass and flowering. This “light recipe” approach eliminates energy waste on wavelengths plants don’t prioritize.

- Spatial Optimization: As a “cool” light source, LEDs can be placed within inches of the canopy. This capability has birthed the modern Vertical Farm, allowing growers to stack production layers and multiply yield per square foot.

- Proven Results: Recent commercial trials have shown that switching to high-efficiency LED systems can increase tomato harvests by up to 60% while simultaneously slashing HVAC energy costs by 50% due to reduced heat loads.

The Hybrid Era: The “Mixed Light” Strategy

The most sophisticated growers today aren’t necessarily choosing one side; they are utilizing a Hybrid Strategy. By combining the deep-penetrating heat of HPS with the spectral precision of LED, facilities can balance winter heating needs with energy-efficient growth stimulation.

Case studies in high-latitude regions have shown that a 1:1 ratio of LED to HPS can reduce overall energy consumption by 15-20% without sacrificing the infrared heat required for certain metabolic processes in cold climates.

The Next Frontier: Laser Diodes (LD) and Beyond

The evolution doesn’t stop at LED. Emerging research into Laser Diode (LD) lighting suggests the next leap in efficiency. Early experiments indicate that 660nm laser light can achieve photosynthetic rates nearly 20% higher than standard LEDs due to its extreme spectral narrowness. While still in the experimental phase for commercial scales, the integration of LD with LED represents the future of ultra-efficient lighting.

Conclusion: Future-Proofing Your Facility

The transition from traditional HID and Fluorescent systems to LED-driven modular systems is the single most impactful upgrade a grower can make. As global energy prices fluctuate and market demands for “cleaner” produce rise, the ability to control every photon becomes a competitive necessity.

Ready to optimize your grow light setup? Discover Nanolux LED Solutions.